The Role of Industrial Scales in Ensuring Accurate Inventory Management

The Role of Industrial Scales in Ensuring Accurate Inventory Management

Blog Article

Why to Choose Industrial Scales for Accurate Weight Dimension in Various Industries

In an era where precision is extremely important, the choice of commercial scales for accurate weight dimension plays an essential duty across varied fields. These ranges not only boost operational effectiveness however likewise make sure conformity with regulatory requirements, influencing everything from production to delivery. Their robust layout and advanced modern technology accommodate various applications, strengthening the requirement for meticulous weight management. Understanding the subtleties of these ranges is crucial for any company intending to maximize processes and minimize costly errors. Yet, the inquiry continues to be: what specific aspects should one consider when choosing the right scale for their distinct operational needs?

Value of Accurate Weight Dimension

In the world of commercial procedures, the significance of precise weight measurement can not be overemphasized. Specific weight dimension is fundamental throughout numerous markets, influencing both functional effectiveness and item high quality - Industrial Scales. It functions as an essential consider stock management, making certain that materials are sufficiently represented, thus reducing waste and lowering expenses

In production, precise weight measurement straight influences production processes. Abnormalities in weight can bring about subpar items or extreme source allowance, affecting general success. Furthermore, in markets such as pharmaceuticals and food production, adherence to rigorous weight specifications is crucial for governing compliance and customer safety and security.

In addition, precise weight measurements facilitate reliable logistics and supply chain management. Effectively considered shipments make certain that transportation costs are enhanced which stock degrees are preserved accurately, therefore avoiding supply lacks or overstock situations.

Sorts Of Industrial Scales

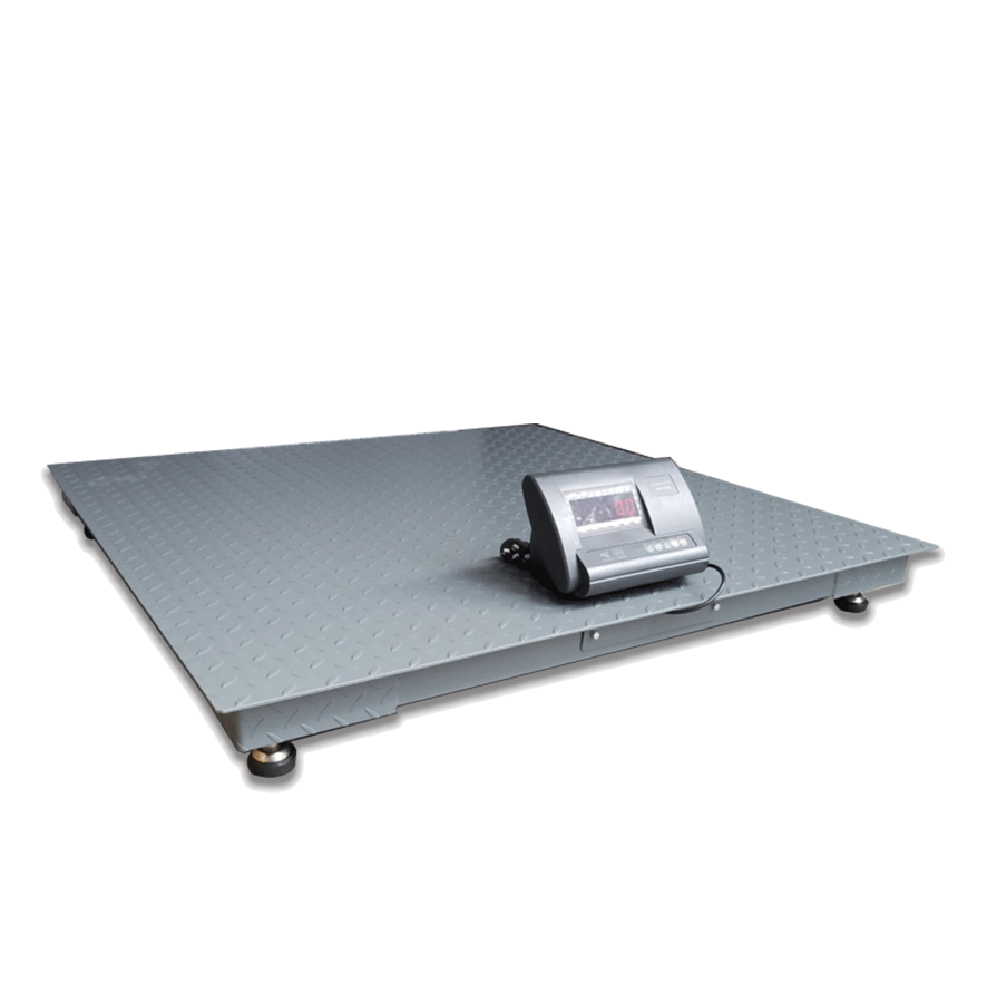

A variety of commercial ranges are readily available, each made to satisfy specific dimension needs throughout diverse markets. Typical types include floor scales, which are robust and suitable for evaluating huge things or pallets in stockrooms and distribution centers. Bench scales are smaller sized and excellent for lighter materials, often made use of in retail settings or producing for specific section control.

An additional group is mobile ranges, which supply the adaptability to be moved quickly around work websites, making them ideal for field operations or temporary configurations. Precision scales, on the other hand, are developed for high accuracy and are frequently made use of in research laboratories and high quality control settings.

Lots cells are essential elements in various industrial ranges, converting force right into an electrical signal for precise analyses. In addition, vehicle scales supply the means to consider hefty automobiles and their tons, making sure conformity with policies and maximizing logistics.

Last but not least, checkweighers automatically compare the weight of items versus pre-programmed limitations, improving quality assurance in assembly line (Industrial Scales). Each type of commercial scale serves an unique feature, dealing with the specific demands of industries such as production, logistics, food processing, and pharmaceuticals

Benefits of Making Use Of Industrial Scales

Consistently utilizing commercial scales uses substantial advantages across different markets. One of the primary advantages is boosted precision in weight dimension, which is vital for maintaining top quality criteria and regulative conformity. Precise dimensions avoid expensive mistakes in delivery, stock, and production administration, inevitably leading to raised operational effectiveness.

Furthermore, commercial scales are made for longevity and robustness, enabling them to stand up to harsh atmospheres typically discovered in manufacturing and warehousing. This strength ensures a long life-span, minimizing the requirement for constant replacements and upkeep costs.

Additionally, utilizing industrial scales improves security and lessens waste. By making certain that items are considered properly, firms can stay clear of straining lorries, which can bring about fines and accidents.

Applications Across Various Industries

Industrial scales play a pivotal duty in countless fields, consisting of production, logistics, food handling, and pharmaceuticals. In manufacturing, these scales are necessary for making certain that raw products are determined precisely, thus maintaining product top quality and uniformity (Industrial Scales). Accuracy in weight dimension straight affects manufacturing efficiency and price administration

In logistics, industrial scales promote the precise considering of deliveries, which is crucial for sticking to delivering policies and optimizing freight prices. Accurate weight information helps simplify procedures and improves supply chain management.

The food handling industry depends greatly on industrial ranges for compliance with health and wellness policies. They are made use of to weigh active ingredients precisely, guaranteeing that formulations satisfy both high quality criteria and legal needs. This is important not just for consumer safety and security however also for keeping brand honesty.

Drug companies make use of industrial ranges to ensure exact does in medication manufacturing, where also the tiniest discrepancy can you could check here have substantial consequences. Conformity with strict governing standards makes accurate weight dimension crucial in this market.

When Choosing Scales,## Aspects to Take Into Consideration.

Selecting the right scale for certain applications calls for careful consideration of a number of variables. First and foremost, the capacity of the scale is vital; it must fit the optimum weight of the things being gauged without surpassing its limits. Additionally, the readability, or smallest increment the scale can precisely show, is crucial for accuracy, specifically in sectors where weight disparities can bring about substantial financial losses or safety concerns.

Environmental conditions also play a significant role in range choice. Scales used in moist or destructive atmospheres may call for specialized products to make sure sturdiness. Similarly, transportability may be important in particular applications, requiring battery-operated and lightweight models.

Final Thought

In verdict, the selection of industrial scales is critical for making sure exact weight dimension throughout varied industries. Their ability to offer exact analyses not only improves operational effectiveness however likewise sustains regulative conformity and stock administration. The adaptability and durability of these scales promote their application in numerous fields, inevitably adding to set you back decrease and improved product quality. Thus, investing in top quality industrial ranges is crucial for companies intending find more info to optimize and preserve high requirements success.

Report this page